Çàãðóçêà...

Çàãðóçêà...Frame House Building

1. The cost of the basic set of frame shield house - 36 624.00 rubles.

Basic configuration:

- The frame is 175 mm thick. Insulation thickness 150 mm, steam and wind insulation on both sides, ventilation gap 20 mm. OSB a plate of 12 mm from two parties. An additional layer of insulation thickness of 50 mm is possible;

- Overlap with a thickness of 175 mm (Interfloor overlapping timber 80x250 mm, insulation 150 mm), vapor barrier. OSB plate 12 mm on both sides;

- The rafter system is 150 mm x 50 mm, the roof lathing is

- Basement timber 200x200, (Laghi 1st floor 80x80);

- Stairs to the second floor (Wooden 2-span.)

2. Cost framed shield at home in bundled - 38 934.00 rubles.

In addition to the base:

- Roofing choice: metal tile or soft (flexible) tiles. Rafter system of timber 150 mm x 50 mm. In the presence of a penthouse insulation 50 mm;

- material for roof covering (“ONDULINE“ euroslate) or metal profile;

- plank floor board (DP 27);

- The lining of the attic floor (wooden "lining")

- windows (wooden STB 939-2013 or plastic STB 1108-98);

- doors:

- Entrance - metal (2100õ900) STB 939-2013

- Interior - wooden paneled STB 939-2013

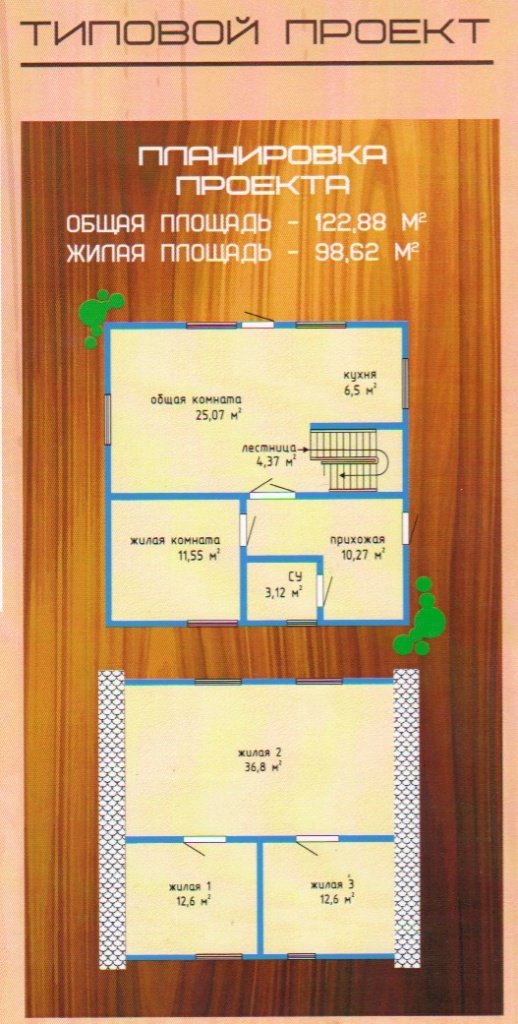

Overall dimensions 8000h8000sm.

Ground floor area - 60.88 m². Attic floor area - 62.00 m²

1. Common room -25.07 m² 6. Staircase -4.37 m²

2. Living room - 11.55 m² 7. Residential 1-12.6 m²

3. Kitchen -6.5 m² 8. Living 2 -36.8 m²

4. SU -3.12 m² 9. Residential 3 -12.6 m²

5. Entrance Hall -10.27 m²

Key Benefits:

- the speed of erection of a house (the construction of wall panels allows you to mount the house quickly and without great expense ‚houses of this type are assembled as a set of 4-8 people by a team for two weeks).

- the possibility of construction at any time of the year;

- high thermal insulation properties;

- superior sound insulation performance;

- ease of construction;

- high seismic resistance;

- manufacturability of finishing works.

Roofing - eSlate “ONDULINE”

Floors - board DP27 (35) STB 1074-2007 from softwood.

Wall covering - siding, wood paneling type "Block House" or others.

Internal walls - a frame from a planed timber section 150x150mm, inside of which a heater is laid and OSB-3 plates 12mm thick or drywall are installed on both sides.

Exterior walls - panel thickness - 175mm, including OSB 3 - 12mm plate, insulation - 150mm, vapor barrier and wind insulation (film), and mounting space for engineering communications - 50mm, closed from inside with OSB plate - 12mm for final finishing .

Ceilings - frame of planed timber section 150x150mm, thickness 250mm, inside of which insulation is laid and OSB-12mm plates are installed on both sides. On the side of the attic, the panel is lined with OSB-12mm (black floor).

Foundation - Columnar of bored piles

Benefits:

- Economical. Requires fewer materials, namely concrete and reinforcement, compared with strip and slab foundation.

- Does not require the manufacture of removable formwork. Permanent formwork is used, the production of which takes a small amount of time.

- The foundation of bored piles can easily be made independently without the involvement of special equipment and hired power.

Doors:

Entrance - metal (2100x900) STB 939-2013

Interior - wooden paneled STB 939-2013.

Windows - wooden STB 939-2013 or plastic STB 1108-98.

It is possible to install stoves or fireplaces in wooden houses of a frame construction, as well as in houses from a bar, a log and a brick. Operating costs and especially the heating costs of these houses are several times lower in comparison with brick and concrete buildings.

Frame systems are made of high-quality planed softwood antiseptic lumber chamber drying. Construction of frame houses is one of the most promising technologies low-rise construction.

Description:

The special design of the frame-panel house reduces the consumption of wood, which makes this technology one of the most affordable in its segment.

The frame-shield house is being built in a surprisingly short time. In just 3 months you will have a full-fledged home, fully ready for interior decoration. This is possible thanks to a special construction technology. All the main elements of the frame-panel house are manufactured at the factory, therefore, at the construction site, it remains only to assemble the finished structure.

The frame-shield house does not shrink, the poem can be erected at any time of the year. Immediately after erection in the frame-shield house it is possible to produce internal and external decoration.

Frame-shield houses are built on a light foundation and do not require additional preparation. The life of the house with full compliance with the construction technology is 30-50 years.

For the manufacture of frame-shield houses is used only natural wood, which makes them environmentally friendly.

The use of flexible, floating structures during construction provides the frame-shield house with high seismic resistance and durability.

Frame-shield houses have good thermal insulation characteristics. The mineral wool used as insulation provides coolness in summer and comfort in winter.

Special processing and impregnation of materials of the frame-shield house makes it fire-resistant, moisture-resistant and keeps from rotting and dampness. The material from which the walls are made of the house, counteracts the occurrence of fungi, bacteria and does not respond to environmental influences.

The work on the finishing of the frame-panel house is not expensive and does not require much labor. The ceiling, walls and floor of the frame-panel house are perfectly even, so immediately after installing the house you are only required to putty the joints, apply primer and you can safely proceed to pasting wallpaper, and laying the flooring.

In the frame-panel houses, you can use standard windows and door blocks, as the window and door openings are perfectly flat and have a standard size.

The structure of the frame-panel house allows you to hide wiring, plumbing and engineering communications in the inner part of the wall, while fully maintaining the aesthetic appearance.

A wide selection of materials is used for the exterior finish of the frame-panel house: decorative plaster, artificial stone, facing brick, ceramic tile, ventilated hinged front panels, wall panels, various types of siding, etc.

The limiting factor here are only your taste and financial capabilities.

The use of only natural material makes frame-panel houses completely safe for permanent residence.

Coniferous wood (pine, spruce) is mainly used to create elements of a frame-panel house, as they retain their properties for a longer time, and with special processing they are practically not subject to decay. Mineral wool plates are used as insulation. Insulation is placed between the racks of the house while providing maximum thermal insulation.

Different types of roofing are used for frame-shield houses: flat, pitched or soft, and it all depends on your personal preferences and project features.

The walls of the frame-panel house have a layered structure. Outside, the frame and walls of the house are sheathed with a vapor-permeable membrane protecting the structure from wind and water. This film has a porous structure, which allows the wood and insulation to "breathe", while remaining in a dry state and passing moisture vapor.

The overlap of a frame-panel house is a horizontal wooden structure that serves to divide a building into floors or vertically separates living space. The overlap cuts off the load and ensures the stability of the house. In addition, it plays the role of additional sound insulation and heat insulation.

Outside, the frame-shield house is finished with modern facing materials: siding, decorative plaster, facing brick or stone, etc.

From the inside, the frame-panel house is covered with vapor-protective films and sheathed with sheets of drywall or OSB slab. For active heating frame-panel houses equip electric air heating systems.

All panels and components (roof systems, floor boards, wall paneling, skirting, windows, doors) are manufactured in our company, where constant quality control takes place, which guarantees the reliability of the house itself.

Materials Used

Vapor barrier film is an important component of roofing or wall coating. The film performs an insulating function, preventing moisture from penetrating into the inner layer of the structure. This is a high-quality product that significantly extends the life of the entire structure.

Mineral wool is a fibrous heat-insulating material on a synthetic binder, obtained exclusively from mineral raw materials - melts, sand, rocks (silicate melts from blast furnace slags, mixtures of sedimentary and igneous rocks are often used).

The basis for the production of mineral wool are minerals. The use of blast furnace slags reduces the quality of the mineral wool insulation - the melting point of the fiber. In this case, a temperature depression of the melt occurs, caused by a high content of iron. Mineral wool is characterized by considerable resistance to high temperatures and the action of chemicals. Mineral wool also has excellent heat and sound insulation properties. In construction, it can almost completely replace asbestos fiber. Currently produced a significant amount of mineral wool, which is widely used in construction. Its main areas of application are thermal insulation of walls and floors.

Block house - one of the most popular finishing materials for walls. Recently, there has been a steady trend towards popularizing the use of natural wood materials during construction.

A block house is a kind of wall paneling, or in other words, a finishing board in which the front side is made under a rounded log. Using the block house for facing the internal or external walls of the house, you can recreate the illusion of a high-grade wooden log house of high quality.